Surplus Equipment Products

Wafer Process Systems Inc. is excited to offer some of our original manufactured equipment at a lower cost. Please review the list of equipment below. If you are interested, please contact us right away.

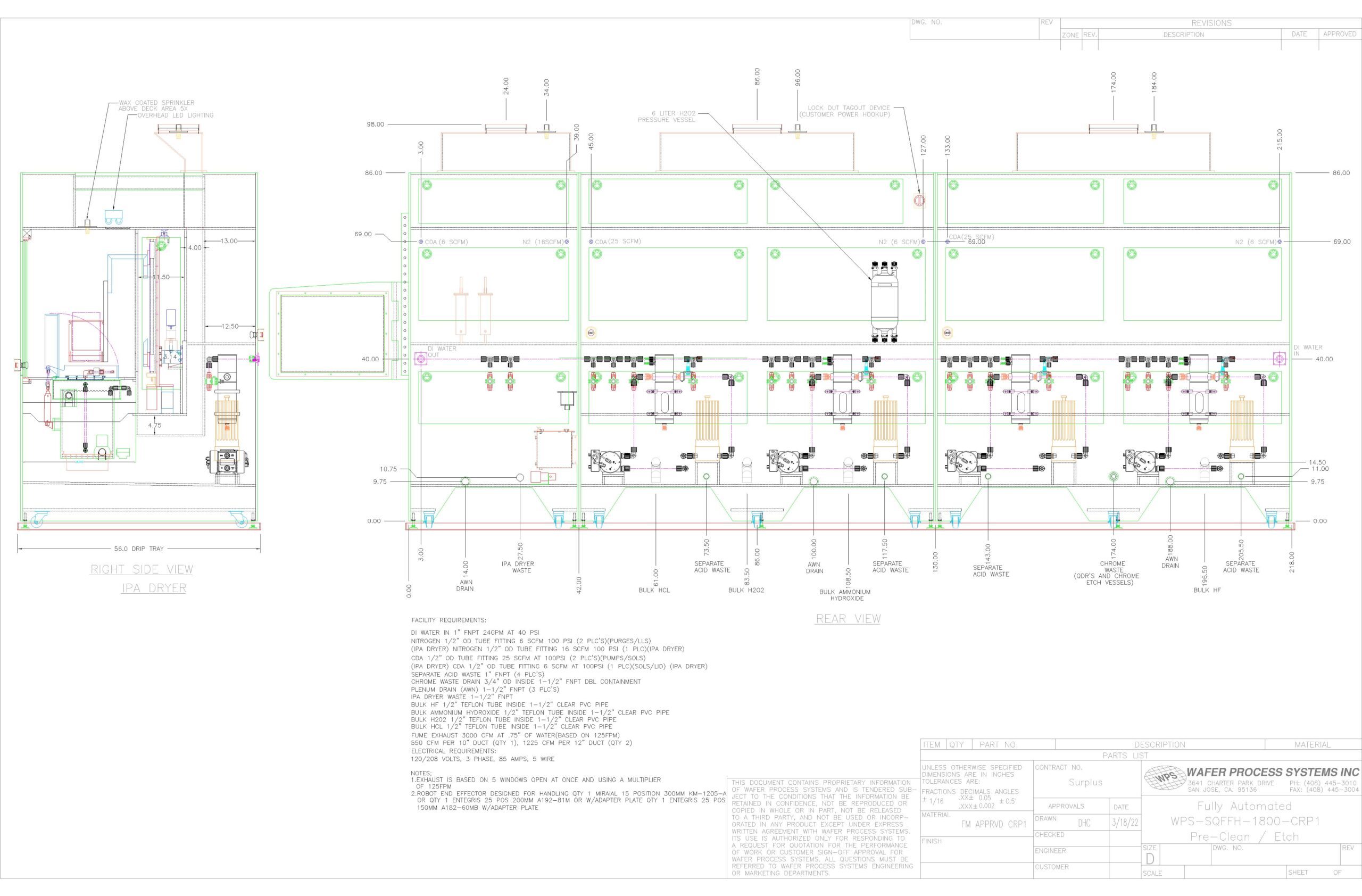

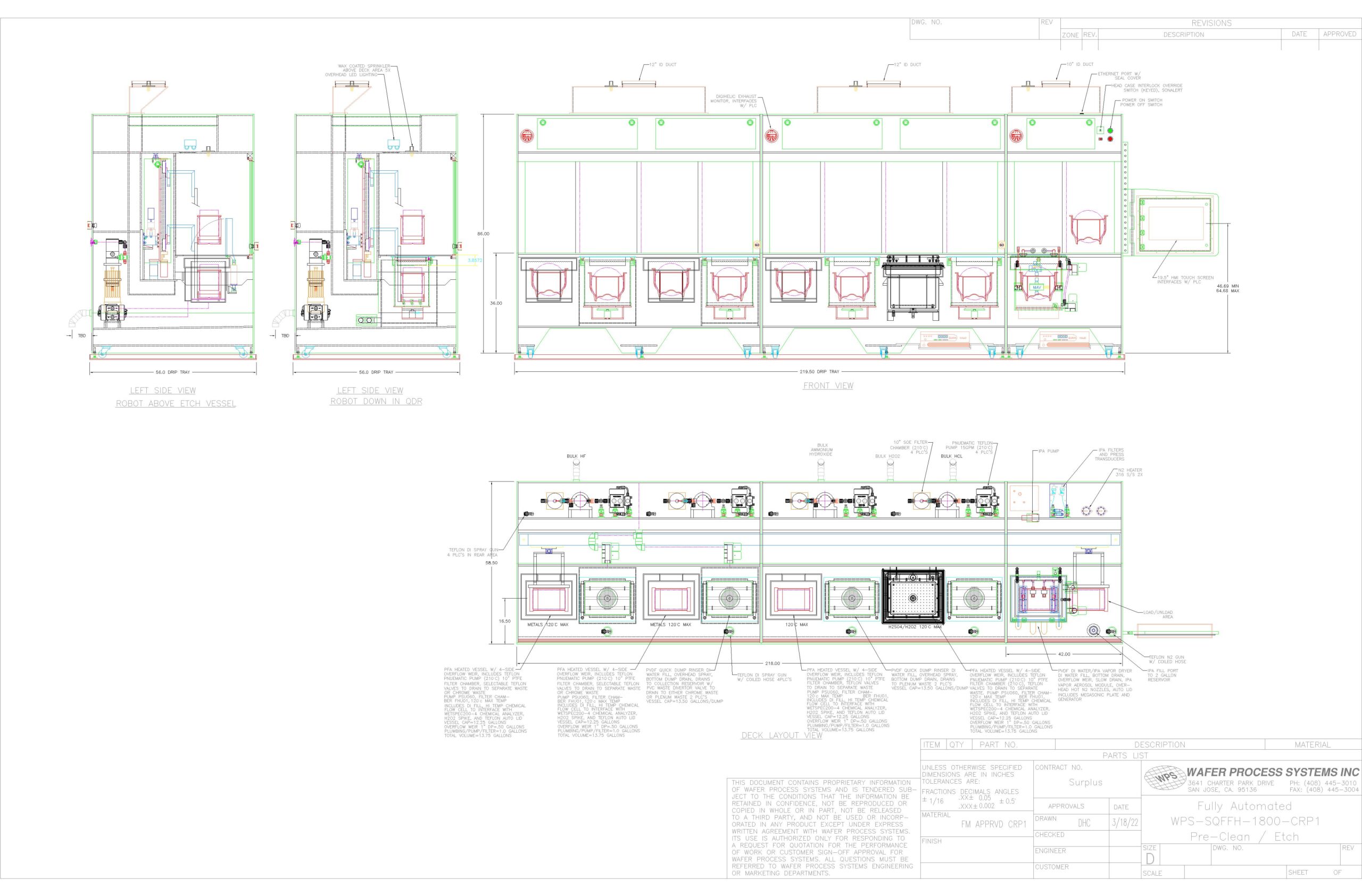

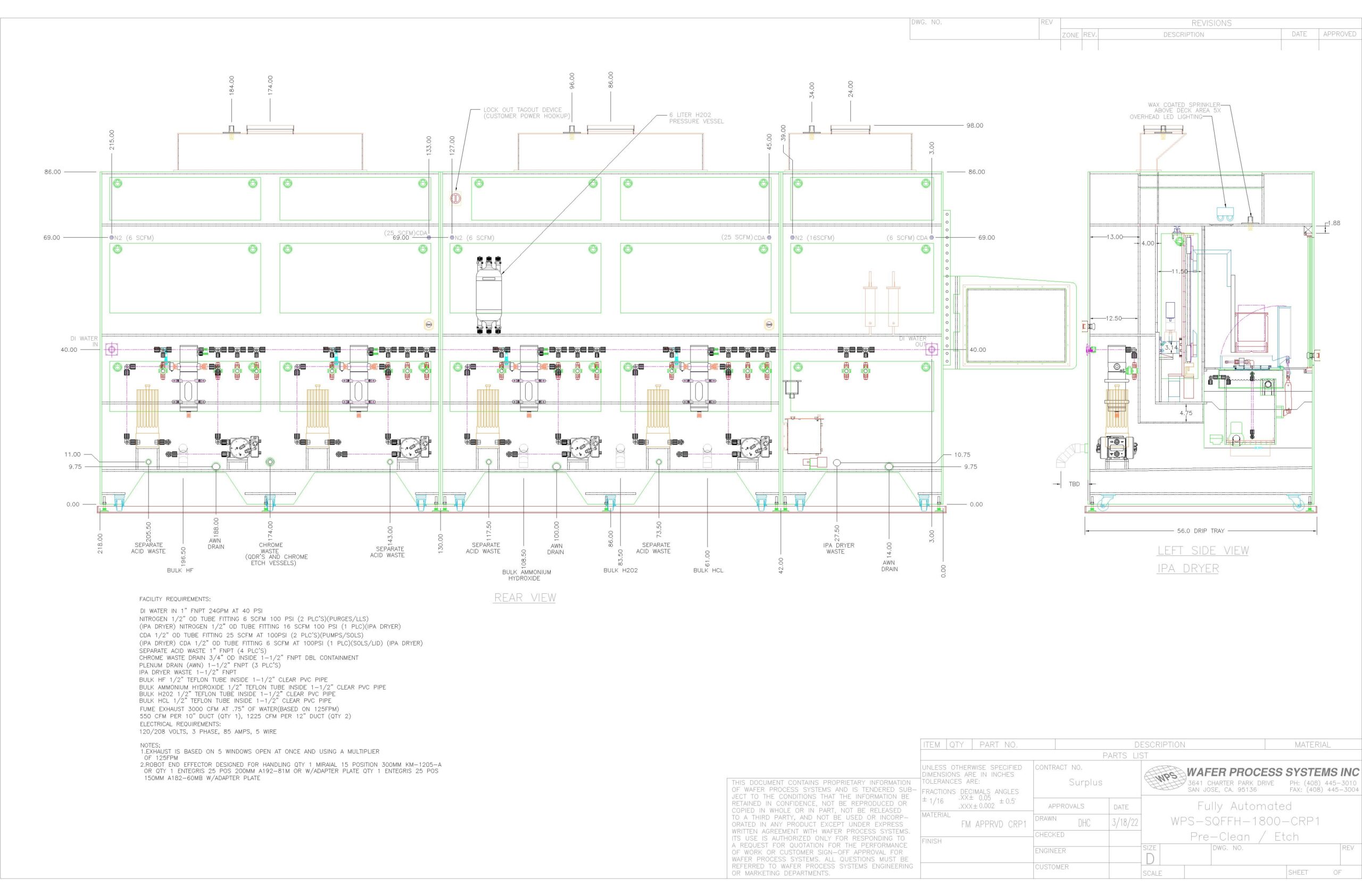

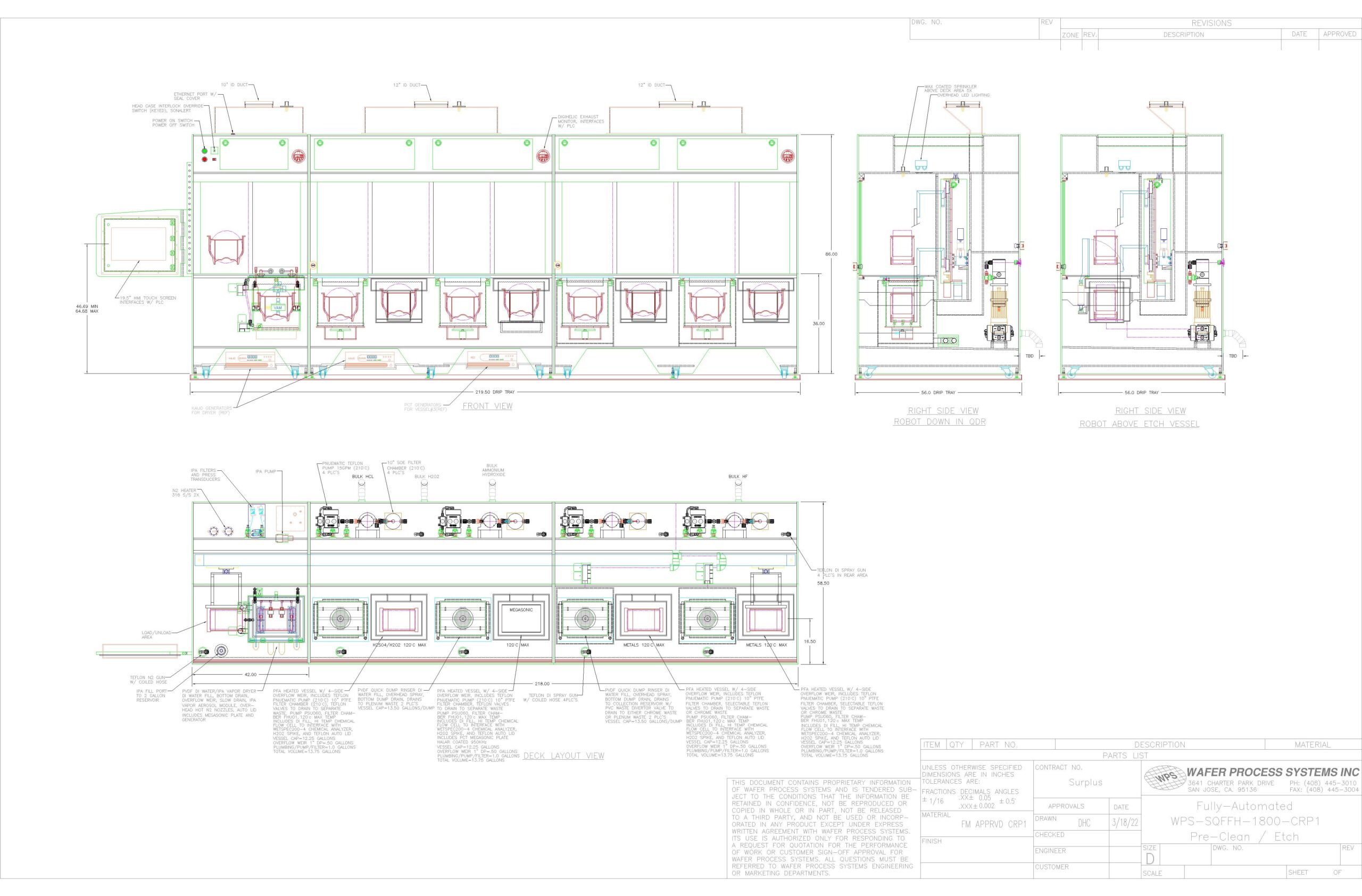

Wafer Process Systems Model WPS-SQFFH – Qty (2)

1800-PVC, 18 foot FM Approved 4910 compliant Modularized CRP1 PVC Rear Access Square Front Fume Hood Wet Process System

Includes:

- Emergency power off circuit with remote mushroom kill switches located on front and rear of cabinet and rotary lock out switch electrical power disconnect.

- All UL, CSA or CE listed high voltage electrical components with GCFI power circuit interrupt for all heat load power circuits and component level circuit fused circuit protection.

- Digihelic® low exhaust monitor with audible and visual alarm to interface with emergency power off circuit.

- N2 purged head case with flow meter and purge pressure interlock to interface with emergency power off circuit.

- Plenum liquid level monitor sensor located in chemical and rinse vessel plenum to interface with emergency power off circuit.

- UL Listed Photo Electronic Smoke Detector to interface with emergency power off circuit. (One sensor located in the electrical compartment).

- FM Approved 4910 compliant CRP1 PVC constructed weldment with integral secondary containment plenum for chemical process vessels and rinse vessels, plenum and back wall exhaust, casters and leg levelers.

- FM Approved 4910 compliant Halar® ECTFE recessed deck with 360° process vessel lip exhaust and secondary exhaust slots.

- FM Approved 4910 compliant CRP1 PVC exhaust transition with integral exhaust damper and wax coated sprinkler head.

- FM Approved 4910 compliant CRP1 PVC front electrical access control panel drawers with interlock switches to interface with emergency power off circuit via over ride switch.

- FM Approved 4910 compliant CRP1 PVC removable upper rear electrical and pneumatic component access panels with interlock switches to interface with emergency power off circuit via over ride switch.

- FM Approved 4910 compliant CRP1 PVC removable lower rear chemical fluid and DI water fluid component access panels.

- Stainless steel N2 and CDA manifold with high pressure and low pressure regulators with gauges. (CDA is used to operate chemical recirculation pumps.)

- Flow through 1” PFA Teflon DI water manifold with PFA 440 Teflon Flaretek tube fittings and PFA 440 Teflon pneumatic diaphragm DI water valves.

- FM Approved 4910 compliant clear HTP® 800 CPVC removable front safety shields.

- FM Approved 4910 compliant CRP1 PVC Drip Tray with 1.5” vertical lip.

- Overhead LED light with FM Approved clear HTP® 800 CPVC diffuser plate.

Wafer Process Systems Model AT-800-5330-L

Automated Linear Transfer System to accommodate one each 300 MM wafer cassette with up to 13 wafers.

Includes:

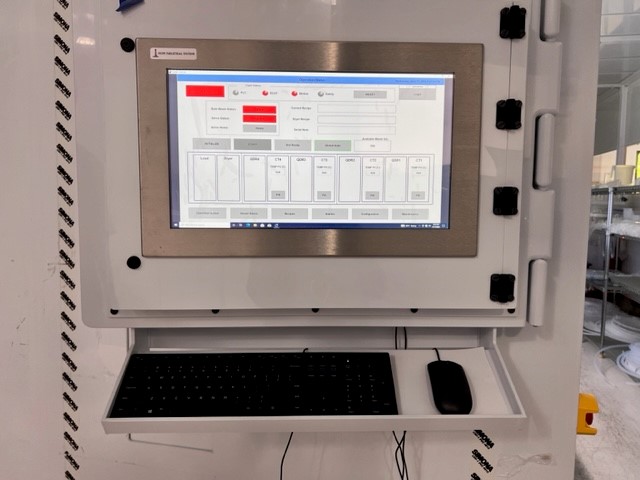

- Omron NB12 TFT, LCD color touch screen display with operational software and operator interface screens for control in automatic mode and control in manual modes for maintenance control of systems.

- Omron CJ2M PLC control sequencer with operational software to perform all positioning movements and interface with process vessel lids and controls.

- Omron MD211 PLC based motion control system with RS-232 interface port, digital I/O port, programmable trapezoidal movement for acceleration and deceleration and programmable interpolation movements between process vessels for reduced transfer times.

- Omron positioning system servo motor driver / amplifier with positioning system servo motors.

- NB Model BG4610A-800H Vertical Linear Tracks Guide Actuator with .5” pitch lead screw drive, pillow block bearings, end limit switches and brake

- Rack and Pinion Horizontal Linear Tracks Guide Actuator with dual Thompson Linear NT23-010-0-RM060-343

- Lower Horizontal Linear Tracks Guide.

- Thompson Linear NT23-010-0-RM060-343 Upper Horizontal Linear Tracks Guide.

- Auto vertical home search upon power up of system with auto horizontal home search upon completion of vertical home. (Home position is located adjacent to IPA dryer).

- Adjustable transfer speed controls via drive motor controls.

- Adjustable vertical agitation speed and stroke length.

- PTFE Teflon transfer arm with PTFE Teflon cassette end effectors to accommodate one each 300 MM wafer cassette with up to 13 wafers.

Wafer Process Systems Model CTAF-300-1-T – Qty (2)

PFA Teflon High Temperature Recirculated Filtration Acid Process Vessel to accommodate one each 300 MM wafer cassette with up to 13 wafers

Includes:

- Omron NB12 TFT, LCD color touch screen display with operational software and operator interface screens for control in automatic mode and control in manual modes for maintenance control of systems.

- Omron CJ2M PLC controlled process vessel with operational software to perform PID temperature control functions, to monitor high temp and low temp process parameters, to monitor over temperature protection, to monitor liquid level interlock, to perform recirculation pump on/off controls and to perform chemical drain on/off controls.

- PFA Teflon internal process vessel (11.0” x 16.5” x 14.0” deep. 11.0 gallons) with center drain on inner vessel, four side scalloped edge over flow and integral overflow sump.

- HC Series, 4kW, 208 VAC, 1 Phase In-Line heater with dual type J over temperature thermocouple, heater element thermal cutoff device (TCO), liquid level interlock to interface with temperature controller for heater on /off control, redundant analog over temperature protection to interface with heater interrupt contactor, FM4910 compliant materials of construction and GCFI heater power circuit protection.

- GCFI heater power circuit protection.

- Process vessel liquid level interlock to interface with chemical recirculation pump on /off controls and in line heater on /off controls.

- Redundant Analog over temperature protection to interface with in line heater interrupt contactor.

- Teflon coated type J process solution immersion thermocouple for monitoring process solution temperature to interface with temperature controller.

- White Knight Model PSU060F-P12, PTFE Teflon pneumatic double bellows pump with existing flow controls (0- 60 LPM @ Ambient to 210 degrees C).

- White Knight Model FHU01-AAP12P12-P4P4P8, all PTFE Teflon Filter Housing with 3/4″ Pillar S300 Liquid Connections rated to 210 ºC to accommodate one (1) each 10” S.O.E. dual 222 o-ring cartridge with two each P-UEA W6-TW6BS Pillar S300 fittings for inlet and outlet of filter housing.

- PFA 440 Teflon pneumatic diaphragm DI Water valves with PFA Teflon Flaretek tube fittings and PFA Teflon tubing for auto DI water rise function and chemical blend function.

- M-2111-F3106-D-Z-018 Rev 000, Ultrasonic Flow Meter, PFA, 3/8” (0 – 8000 mL/min, Z-shape calibration included), DSP Converter with display (24VDC, Signal output: 4-20mA, 2 Digital Outputs, 1 Digital Input, RS485) for monitoring low volumetric flow of dispensed DI water.

- PFA Teflon tubing and PFA Teflon Flaretek tube fittings for chemical recirculation fluid path and chemical drain fluid path.

- Teflon drain to drain to separate acid waste connection to interface with Bulk Waste Chemical Collection

- Storage weldment or to separate acid waste connection to interface with facilities acid waste neutralization system with software based programmable drain temperature interlock set point and drain activation timer.

- PTFE Teflon hinged lid with two PVC pneumatic cylinder actuators with Hall Effect sensors to interface with Omron PLC positioning system controls to open and close lid during automated operations and manual open

WetSpec200-4 NIR Chemical Analyzer – Qty (Lot)

In-line Concentration Near Infrared Absorption Spectra Flow Cells on four each Wafer Process Systems Model CTAF-300-1-T, PFA Teflon High Temperature Recirculated Filtration Acid Process Vessel recirculation path, post filter housing to perform chemical concentration monitoring of process chemistry.

Includes:

- WetSpec200-4 NIR Chemical Analyzer – 4 channel A8041000010-F

- Four each high temperature 3/4” Nippon Pillar Flow Cell for chemical vessel vessel’s #1, #2, #3 and #4. P/N A8004131095

- CDA purge Flow Cell enclosures with remote flow meter control for each ¾” cell. P/N A8004130520

- Fiber cable – 6m length – PEEK connectors for Flow Cell to Analyzer. P/N A8004150045-006

- Custom Chemical modeling – 1 set included per channel (SC1, SC2, HF, H2SO4:H2O2)

- Omron NX-AD3204 Analog Input Module to interface with WetSpec200-4 NIR Chemical Analyzer.

Wafer Process Systems Model RMQD-300-1-K – Qty (2)

Natural Polyvinylidene Fluoride Quick Dump Rinser / Cascade Rinser (11.0” x 16.5” x 14.0” deep) to accommodate one each 300 MM wafer cassette with up to 13 wafers titled “DI Water Rinser.

Includes:

- Omron NB12 TFT, LCD color touch screen display with operational software and operator interface screens for control in automatic mode and control in manual modes for maintenance control of systems.

- Omron CJ2M PLC controlled process vessel with operational software to perform DI water fill sequence DI water drain sequence, auto dump sequence and pre quench sequence.

- Natural Polyvinylidene Fluoride (PVDF) process vessel (11.0” x 16.5” x 14.0” deep. 10.0 gallons) with overhead DI water spray nozzles and four (4) sided over flow.

- PFA 440 Teflon pneumatic diaphragm DI Water valves with PFA Teflon Flaretek tube fittings and PFA Teflon tubing.

- Programmable auto dump sequence. (Cycles QDR for one dump and one fill during idle mode. Programmable from 1-99 minutes.) and programmable pre-quench sequence. (First dump delay timer. Programmable from 1-99 seconds).

- Adjustable low flow DI water to overhead spray and bottom fill. (Idle mode flow control) and adjustable high flow DI water to overhead spray and bottom fill. (Cycle mode flow control).

Wafer Process Systems QDR-LDT Series, Model CR-LDT-300-1-K

Kynar PVDF Cascade Rinse / Liquid Diffusion Technology IPA Dryer to accommodate one each 300 MM wafer cassette with up to 13 wafers titled “DI Water Rinser / IPA Dryer.

Includes:

- Omron NB12 TFT, LCD color touch screen display with operational software and operator interface screens for control in automatic mode and control in manual modes for maintenance control of systems.

- Omron CJ2M PLC DI Water Clean / IPA Liquid Diffusion Dryer Process Vessel with operational software to perform DI water cleaning and IPA drying sequence, to perform IPA aerosol generation sequence, to perform DI Water fill and drain sequence, to perform auto dump sequence and to perform pre-quench sequence, to monitor liquid level interlock and to perform process vessel lid open and close function.

- Kynar PVDF process vessel with 360° scalloped edge overflow with 1.5” high flow overflow/vent port to drain to DI water waste, 1.5” high flow drain port to drain to DI water waste, ½” micro adjustable liquid diffusion drain for IPA drying sequence controlled drain and PFA IPA aerosol injection nozzle.

- PFA 440 Teflon pneumatic diaphragm IPA aerosol dispense valve with PFA Teflon Flaretek tube fittings and PFA Teflon tubing to interface with IPA aerosol delivery system.

- Stainless steel pneumatic bellows Nitrogen IPA standby valve with stainless steel metering valve, stainless steel tube fittings and tubing to interface with VAM for VAM purging.

- Stainless steel pneumatic bellows Nitrogen IPA dispense valve with stainless steel metering valve, stainless steel tube fittings and tubing to interface with VAM for IPA aerosol dispense.

- Stainless steel pneumatic bellows Nitrogen low flow purge valve with stainless steel metering valve, stainless steel tube fittings and tubing to interface with inline N2 heater for heater purging.

- Stainless steel pneumatic bellows Nitrogen medium flow purge valve with stainless steel metering valve, stainless steel tube fittings and tubing to interface with inline N2 heater for drying.

- Stainless steel pneumatic bellows Nitrogen high flow purge valve with stainless steel tube fittings and tubing to interface with inline N2 heater

- Dual 3kW 208V 316 stainless steel in-line nitrogen heater with integral type J over temperature thermocouple, heater element thermal cutoff device (TCO) and GCFI heater power circuit protection.

- PEEK constructed Heater N2 blow dry manifolds located in lid with 316 stainless steel in line filter.

- 316 pressure regulator with 316 stainless steel in-line pre filter prior to manifold.

- PEEK constructed IPA aerosol generation system with PTFE Teflon VAM diverter valve with PFA Teflon Flaretek tube fitting and tubing.

- 316 stainless steel IPA reservoir with high and low liquid level interlock and IPA suction and return ports to interface with IPA recirculation pump suction and VAM return line.

- PFA 440 Teflon pneumatic diaphragm DI Water valves with PFA Teflon Flaretek tube fittings and PFA Teflon tubing.

- Programmable auto dump sequence. (Cycles for one fill and one drain during idle mode. Programmable from 1-99 minutes.).

- Programmable pre-quench sequence. (First dump delay timer. Programmable from 1-99 seconds).

- Adjustable high flow DI water to bottom fill. (Cycle mode flow control).

- Kynar PVDF hinged lid with pneumatic cylinder actuator with Hall Effect switches to interface with positioning system controls to open and close lid and manual open / close controls via PLC operator interface touch screen.

- Removable Kynar PVDF cassette support rack to accommodate one each 300 MM carrier.

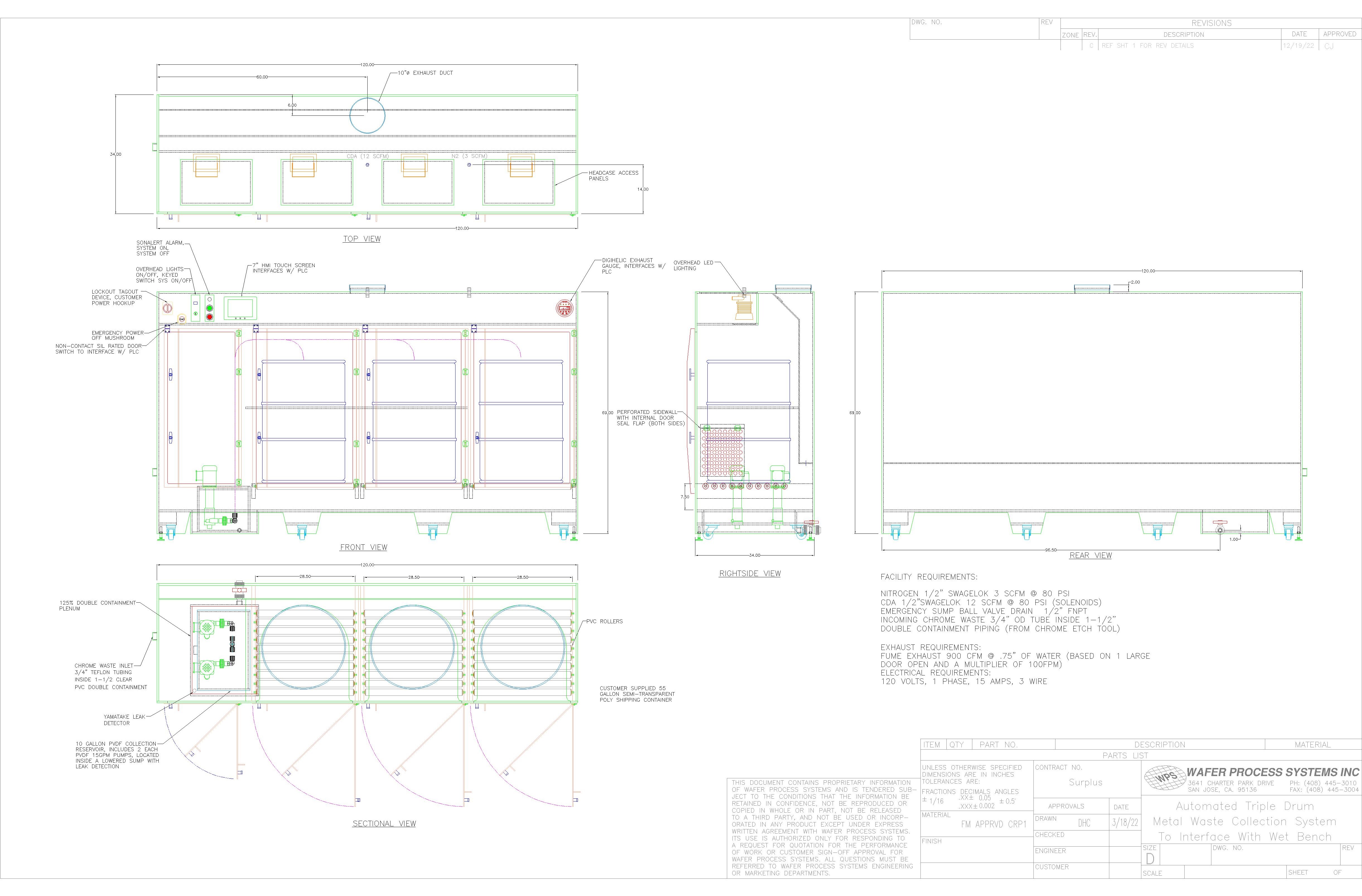

FM Approved Noveon® PVC-C

Bulk HF Acid / Metal Waste Chemical Collection Storage weldment (120” W x 34” D x 72” H) to accommodate three each customers’ 55 Gallon Semi-Transparent Poly Shipping Container to interface with Metal Rinse Quick Dump Rinser waste drain.

Includes:

-

Omron PLC Controller node with 7” color touch screen and operational software to perform waste effluent transfer from primary chemical collection reservoir to waste transport drums, to monitor liquid level of primary chemical collection reservoir, to monitor liquid level of waste transport drum, to monitor exhaust via Digihelic Low Exhaust Monitor, to control main waste effluent shut of valve and to monitor leak detection sensors.

-

FM Approved Noveon® PVC-C constructed weldment with 125% secondary containment, back wall updraft exhaust with 10” ID exhaust transition to interface with customers exhaust system, exhaust port on side wall of bulk chemical delivery weldment with damper plate to eliminate excessive vacuum from exhaust while door is closed. Includes stainless steel casters for transporting and stainless steel leg levelers for final installation.

-

Clear CPVC hinged front door with Southco hinges and ¼ turn latches with door interlock switch to interface with Omron Zen PLC controller.

-

Rolcon drum rollers with corrosion resistant PVC encapsulated roller face and spring retained axles located in collection section of weldment.

-

1.5” FNPT normally closed PVDF pneumatic main shut off valve to interrupt waste effluent from wet bench in the event of a secondary leak detection, high/high level condition within the primary chemical collection reservoir or a collection drum full condition.

-

Yamatake secondary containment leak detection sensor located in weldment plenum to interface with Omron Zen PLC Controller.

-

Integral 10 gallon Natural Polyvinylidene Fluoride (PVDF) primary chemical collection reservoir with slopped bottom to corner pump suction port, reservoir vent port and multi-level chemical reservoir liquid level interlocks to interface with PLC controller.

-

Dual Natural Polyvinylidene Fluoride (PVDF) submersible pumps located in 10 gallon primary chemical collection reservoir for transfer of waste effluent into customers’ 55 Gallon Semi-Transparent Poly Shipping Container.

-

Flowline EchoPod UG01-0001-41, reflective ultrasonic level transmitter with PVDF transducer, 4-20 mA two wire output to interface with PLC, ±0.2% of range accuracy, 4.9 foot maximum range with a 2” beam width, 2” MNPT connection and polypropylene IP68 rated enclosure. (For Waste Drum Level Sensing.)

-

PVDF Teflon bellows pneumatic switch over valves for diverting waste effluent from full drum to empty drum.

-

Remote EPO mushroom switch on bulk chemical cabinet to interface with Omron PLC controller.

-

Digihelic Low Exhaust Monitor on bulk chemical cabinet to interface with Omron PLC controller.

-

12 VDC GLW® 10w 24 VDC LED Waterproof Flood Light.

-

Bulk chemical delivery storage weldment secondary containment drain connection with 1” LOTO ball valve.

-

Keyed service interlock to interface with Omron PLC Controller.

Wafer Process Systems Model CDS-1-4-T

Single Source Four Point of Use Automatic Chemical Dispense System located in Wafer Process Systems Model WPS-SQFFH-1800-PVC, 18 foot FM Approved 4910 compliant Modularized CRP1 PVC Rear Access Square Front Fume Hood Wet Process System titled “Pre-Clean / Etch Wet Bench.” to interface with Chemical Process Vessels titled “H2O2 Dispense / Spiking.

Includes:

-

153-601-XXX, 6” diameter six liter PFA Teflon Custom Pressure Vessels for point of use storage of 30 % H2O2 process chemical from 100 liter shipping container for dispensing under pressure to all four chemical process vessels located in weldment. Includes intrinsically safe four position liquid level sensing (low level alert, low level alarm, high level alert and high level alarm).

-

Futurestar Auto Valve Model 6AM-4S-1B-209U, with a flow control range 0.25-5 LPM at 10-30 psid and 4-20 mA output for Closed Loop Control and ½” inlet, ½” outlet both S300 connections for fluid flow control of H2O2 during dispense sequence for mixed ratios blending for Bay # 1, Bay # 3A, Bay # 3B and Bay #5.

-

M-2111-F3104-D-Z-047 Rev 000, Ultrasonic Flow Meter, PFA, 3/8” (0 – 8000 mL/min, Z-shape calibration included), DSP Converter with display (24VDC, Signal output: 4-20mA, 2 Digital Outputs, 1 Digital Input, RS485) for monitoring low volumetric flow of recirculated DI water.

-

Four each PFA 440 Teflon pneumatic diaphragm chemical dispense valves to interface with chemical process vessels to be controlled by Omron PLC controller for mixed ratios blending and spiking.

-

PFA Teflon tubing with PFA Teflon Flaretek Fittings for Chemical fluid paths.

Wafer Process Systems PFA Teflon DI Water – Qty (10)

hand spray located in recessed well in weldment work surface and in rear plumbing compartment.

Bar Code Scanner

For lot identification and data logging of process parameters to include local computer and monitor, bar code reader and ethernet switch for communication from PLC to local PC and from local PC to facilities network. The data file would be generated in an Excel format (.xls or .xlsx) from a comma delimited / comma-separated values .(CSV) file for the logging and in order to communicate with your facilities network.

Includes:

-

Data Logging to be store to the local computer hard drive for retrieval via USB memory card or via ethernet communications for on-line report of lot process parameters.

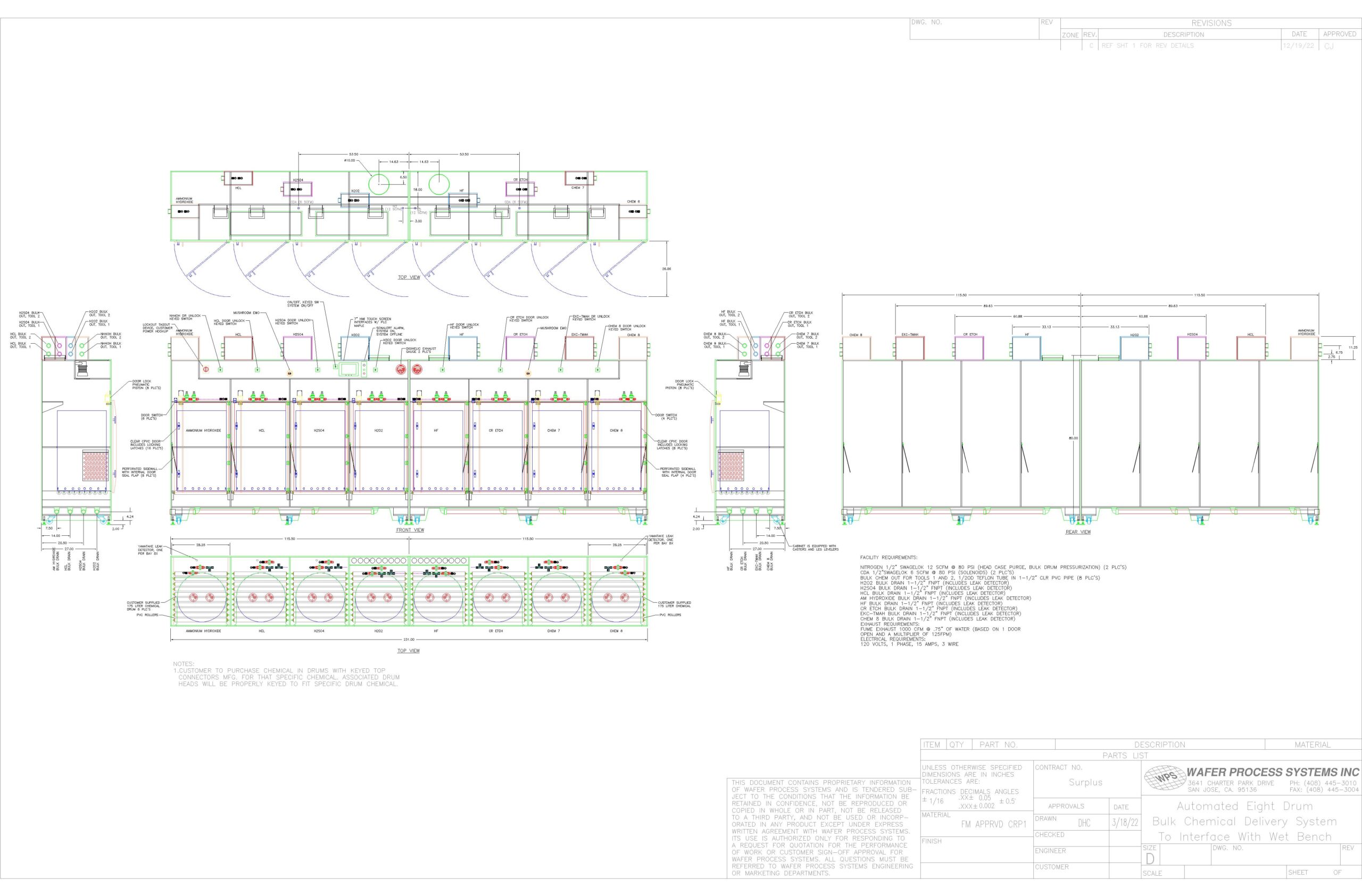

Modularized CRP1-PVC-BCD-8-8 – Qty (1)

Eight Source, Eight Point of Use Dispense Bulk Chemical Delivery System with FM Approved CRP1 PVC constructed storage weldment (two sections at 102” W x 34” D x 75.5” H) to accommodate eight each customers’ Entegris FluoroPure® 100 Liter PFA Pressure Vessels and to interface with two each Wafer Process Systems Model WPS-SQFFH-1800-PVC-C, 18 foot FM Approved 4910 compliant Modularized PVC-C Rear Access Square Front Fume Hood Wet Process System titled “Pre-Clean / Etch Wet Bench

FM Approved 4910 compliant CRP1 PVC – Qty (1)

bulk chemical delivery storage weldment to accommodate one each customers’ 55 gallon drum shipping container titled “Chemical #1 / Ammonium Hydroxide” to interface with two each Wafer Process Systems Model WPS-SQFFH-1800-PVC, 18 foot FM Approved 4910 compliant Modularized CRP1 PVC Rear Access Square Front Fume Hood Wet Process System titled “Pre-Clean / Etch Wet Bench.”

Includes:

-

Clear CPVC hinged front door with Southco hinges and ¼ turn latches with door interlock switch to interface with Omron PLC controller.

-

Rolcon drum rollers with corrosion resistant PVC encapsulated roller face and spring retained axles.

-

Integral leak detection sensor located in weldment plenum to interface with Omron PLC Controller.

-

Shipping container low fluid sensor located in line from the container to the point of use chemical process vessel.

-

Machined Buttress Drum Adaptor for siphon port connection to shipping container drum.

-

Remote EPO mushroom switch on bulk chemical cabinet to interface with Omron PLC controller.

-

Digihelic Low Exhaust Monitor on bulk chemical cabinet to interface with Omron PLC controller.

-

12 VDC GLW® 10w 24 VDC LED Waterproof Flood Light.

-

Bulk chemical delivery storage weldment secondary containment drain connection with 1” ball valve.

-

White Knight Model PSA060 F12, PTFE Teflon pneumatic double bellows pump with flow controls (0- 60 LPM @ Ambient to 100 degrees C) for chemical dispensing to point of use chemical process vessel.

-

Yamatake secondary containment leak detection sensor located in weldment plenum to interface with Omron Zen PLC Controller.

-

Flowline EchoPod UG01-0001-41, reflective ultrasonic level transmitter with PVDF transducer, 4-20 mA two wire output to interface with PLC, ±0.2% of range accuracy, 4.9 foot maximum range with a 2” beam width, 2” MNPT connection and polypropylene IP68 rated enclosure. (For Waste Drum Level Sensing.)

-

PFA Teflon 2-way bulk chemical dispense valve located in chemical delivery storage weldment to interface with point of use chemical process vessel to be controlled by Omron PLC controller.

-

Futurestar Auto Valve Model 6BJ-4S-1B-204U, with a flow control range 0.25-18 LPM at 10-30 psid and 4-20 mA output for Closed Loop Control and ½” inlet, ½” outlet both S300 connections.

-

M-2111-F4110-D-Z-010 REV 002, Ultrasonic Flow Meter, PFA, ½” (0 – 18 LPM, Z-shape calibration included), DSP Converter with display (24VDC, Signal output: 4-20mA, 2 Digital Outputs, 1 Digital Input, RS485) for monitoring chemical dispense flow rate.

-

Keyed service interlock to interface with Omron PLC Controller.

-

PFA Teflon tubing with PFA Teflon Primelock Fittings for Chemical fluid paths.

FM Approved 4910 compliant CRP1 PVC – Qty (1)

Bulk chemical delivery storage weldment to accommodate one each customers’ 55 gallon drum shipping container titled “Chemical #3 / H2SO4 Acid” to interface with two each Wafer Process Systems Model WPS-SQFFH-1800-PVC, 18 foot FM Approved 4910 compliant Modularized CRP1 PVC Rear Access Square Front Fume Hood Wet Process System titled “Pre-Clean / Etch Wet Bench.”

Includes:

- Clear CPVC hinged front door with Southco hinges and ¼ turn latches with door interlock switch to interface with Omron PLC controller.

- Rolcon drum rollers with corrosion resistant PVC encapsulated roller face and spring retained axles.

- Integral leak detection sensor located in weldment plenum to interface with Omron PLC Controller.

- Shipping container low fluid sensor located in line from the container to the point of use chemical process vessel.

- Machined Buttress Drum Adaptor for siphon port connection to shipping container drum.

- Remote EPO mushroom switch on bulk chemical cabinet to interface with Omron PLC controller.

- Digihelic Low Exhaust Monitor on bulk chemical cabinet to interface with Omron PLC controller.

- 12 VDC GLW® 10w 24 VDC LED Waterproof Flood Light.

- Bulk chemical delivery storage weldment secondary containment drain connection with 1” ball valve.

- White Knight Model PSA060 F12, PTFE Teflon pneumatic double bellows pump with flow controls (0- 60 LPM @ Ambient to 100 degrees C) for chemical dispensing to point of use chemical process vessel

- Yamatake secondary containment leak detection sensor located in weldment plenum to interface with Omron Zen PLC Controller.

- Flowline EchoPod UG01-0001-41, reflective ultrasonic level transmitter with PVDF transducer, 4-20 mA two wire output to interface with PLC, ±0.2% of range accuracy, 4.9 foot maximum range with a 2” beam width, 2” MNPT connection and polypropylene IP68 rated enclosure. (For Waste Drum Level Sensing.)

- PFA Teflon 2-way bulk chemical dispense valve located in chemical delivery storage weldment to interface with point of use chemical process vessel to be controlled by Omron PLC controller.

- Futurestar Auto Valve Model 6BJ-4S-1B-204U, with a flow control range 0.25-18 LPM at 10-30 psid and 4-20 mA output for Closed Loop Control and ½” inlet, ½” outlet both S300 connections.

- M-2111-F4110-D-Z-010 REV 002, Ultrasonic Flow Meter, PFA, ½” (0 – 18 LPM, Z-shape calibration included), DSP Converter with display (24VDC, Signal output: 4-20mA, 2 Digital Outputs, 1 Digital Input, RS485) for monitoring chemical dispense flow rate.

- Keyed service interlock to interface with Omron PLC Controller.

- PFA Teflon tubing with PFA Teflon Primelock Fittings for Chemical fluid paths.

FM Approved 4910 compliant CRP1 PVC – Qty (1)

Bulk chemical delivery storage weldment to accommodate one each customers’ 55 gallon drum shipping container titled “Chemical #4 / Hydrogen Peroxide” to interface with two each Wafer Process Systems Model WPS-SQFFH-1800-PVC, 18 foot FM Approved 4910 compliant Modularized CRP1 PVC Rear Access Square Front Fume Hood Wet Process System titled “Pre-Clean / Etch Wet Bench.”

Includes:

-

Clear CPVC hinged front door with Southco hinges and ¼ turn latches with door interlock switch to interface with Omron PLC controller.

-

Rolcon drum rollers with corrosion resistant PVC encapsulated roller face and spring retained axles.

-

Integral leak detection sensor located in weldment plenum to interface with Omron PLC Controller.

-

Shipping container low fluid sensor located in line from the container to the point of use chemical process vessel.

-

Machined Buttress Drum Adaptor for siphon port connection to shipping container drum.

-

Remote EPO mushroom switch on bulk chemical cabinet to interface with Omron PLC controller.

-

Digihelic Low Exhaust Monitor on bulk chemical cabinet to interface with Omron PLC controller.

-

12 VDC GLW® 10w 24 VDC LED Waterproof Flood Light.

-

Bulk chemical delivery storage weldment secondary containment drain connection with 1” ball valve.

-

White Knight Model PSA060 F12, PTFE Teflon pneumatic double bellows pump with flow controls (0- 60 LPM @ Ambient to 100 degrees C) for chemical dispensing to point of use chemical process vessel.

-

Yamatake secondary containment leak detection sensor located in weldment plenum to interface with Omron Zen PLC Controller.

-

Flowline EchoPod UG01-0001-41, reflective ultrasonic level transmitter with PVDF transducer, 4-20 mA two wire output to interface with PLC, ±0.2% of range accuracy, 4.9 foot maximum range with a 2” beam width, 2” MNPT connection and polypropylene IP68 rated enclosure. (For Waste Drum Level Sensing.)

-

PFA Teflon 2-way bulk chemical dispense valve located in chemical delivery storage weldment to interface with point of use chemical process vessel to be controlled by Omron PLC controller.

-

Futurestar Auto Valve Model 6BJ-4S-1B-204U, with a flow control range 0.25-18 LPM at 10-30 psid and 4-20 mA output for Closed Loop Control and ½” inlet, ½” outlet both S300 connections.

-

M-2111-F4110-D-Z-010 REV 002, Ultrasonic Flow Meter, PFA, ½” (0 – 18 LPM, Z-shape calibration included), DSP Converter with display (24VDC, Signal output: 4-20mA, 2 Digital Outputs, 1 Digital Input, RS485) for monitoring chemical dispense flow rate.

-

Keyed service interlock to interface with Omron PLC Controller.

-

PFA Teflon tubing with PFA Teflon Primelock Fittings for Chemical fluid paths.

FM Approved 4910 compliant CRP1 PVC – Qty (1)

Bulk chemical delivery storage weldment to accommodate one each customers’ 55 gallon drum shipping container titled “Chemical #5 / Hydrofluoric Acid” to interface with two each Wafer Process Systems Model WPS-SQFFH-1800-PVC, 18 foot FM Approved 4910 compliant Modularized CRP1 PVC Rear Access Square Front Fume Hood Wet Process System titled “Pre-Clean / Etch Wet Bench.”

Includes:

- Clear CPVC hinged front door with Southco hinges and ¼ turn latches with door interlock switch to interface with Omron PLC controller.

- Rolcon drum rollers with corrosion resistant PVC encapsulated roller face and spring retained axles.

- Integral leak detection sensor located in weldment plenum to interface with Omron PLC Controller.

- Shipping container low fluid sensor located in line from the container to the point of use chemical process vessel.

- Machined Buttress Drum Adaptor for siphon port connection to shipping container drum.

- Remote EPO mushroom switch on bulk chemical cabinet to interface with Omron PLC controller.

- Digihelic Low Exhaust Monitor on bulk chemical cabinet to interface with Omron PLC controller.

- 12 VDC GLW® 10w 24 VDC LED Waterproof Flood Light.

- Bulk chemical delivery storage weldment secondary containment drain connection with 1” ball valve.

- White Knight Model PSA060 F12, PTFE Teflon pneumatic double bellows pump with flow controls (0- 60 LPM @ Ambient to 100 degrees C) for chemical dispensing to point of use chemical process vessel.

- Yamatake secondary containment leak detection sensor located in weldment plenum to interface with Omron Zen PLC Controller.

- Flowline EchoPod UG01-0001-41, reflective ultrasonic level transmitter with PVDF transducer, 4-20 mA two wire output to interface with PLC, ±0.2% of range accuracy, 4.9 foot maximum range with a 2” beam width, 2” MNPT connection and polypropylene IP68 rated enclosure. (For Waste Drum Level Sensing.)

- PFA Teflon 2-way bulk chemical dispense valve located in chemical delivery storage weldment to interface with point of use chemical process vessel to be controlled by Omron PLC controller.

- Futurestar Auto Valve Model 6BJ-4S-1B-204U, with a flow control range 0.25-18 LPM at 10-30 psid and 4-20 mA output for Closed Loop Control and ½” inlet, ½” outlet both S300 connections.

- M-2111-F4110-D-Z-010 REV 002, Ultrasonic Flow Meter, PFA, ½” (0 – 18 LPM, Z-shape calibration included), DSP Converter with display (24VDC, Signal output: 4-20mA, 2 Digital Outputs, 1 Digital Input, RS485) for monitoring chemical dispense flow rate.

- Keyed service interlock to interface with Omron PLC Controller.

- PFA Teflon tubing with PFA Teflon Primelock Fittings for Chemical fluid paths.

FM Approved 4910 compliant CRP1 PVC – Qty (1)

Bulk chemical delivery storage weldment to accommodate one each customers’ 55 gallon drum shipping container titled “Chemical #6 / CR Etchant” to interface with two each Wafer Process Systems Model WPS-SQFFH-1800-PVC, 18 foot FM Approved 4910 compliant Modularized CRP1 PVC Rear Access Square Front Fume Hood Wet Process System titled “Pre-Clean / Etch Wet Bench.”

Includes:

- Clear CPVC hinged front door with Southco hinges and ¼ turn latches with door interlock switch to interface with Omron PLC controller.

- Rolcon drum rollers with corrosion resistant PVC encapsulated roller face and spring retained axles.

- Integral leak detection sensor located in weldment plenum to interface with Omron PLC Controller.

- Shipping container low fluid sensor located in line from the container to the point of use chemical process vessel.

- Machined Buttress Drum Adaptor for siphon port connection to shipping container drum.

- Remote EPO mushroom switch on bulk chemical cabinet to interface with Omron PLC controller.

- Digihelic Low Exhaust Monitor on bulk chemical cabinet to interface with Omron PLC controller.

- 12 VDC GLW® 10w 24 VDC LED Waterproof Flood Light.

- Bulk chemical delivery storage weldment secondary containment drain connection with 1” ball valve.

- White Knight Model PSA060 F12, PTFE Teflon pneumatic double bellows pump with flow controls (0- 60 LPM @ Ambient to 100 degrees C) for chemical dispensing to point of use chemical process vessel.

- Yamatake secondary containment leak detection sensor located in weldment plenum to interface with Omron Zen PLC Controller.

- Flowline EchoPod UG01-0001-41, reflective ultrasonic level transmitter with PVDF transducer, 4-20 mA two wire output to interface with PLC, ±0.2% of range accuracy, 4.9 foot maximum range with a 2” beam width, 2” MNPT connection and polypropylene IP68 rated enclosure. (For Waste Drum Level Sensing.)

- PFA Teflon 2-way bulk chemical dispense valve located in chemical delivery storage weldment to interface with point of use chemical process vessel to be controlled by Omron PLC controller.

- Futurestar Auto Valve Model 6BJ-4S-1B-204U, with a flow control range 0.25-18 LPM at 10-30 psid and 4-20 mA output for Closed Loop Control and ½” inlet, ½” outlet both S300 connections.

- M-2111-F4110-D-Z-010 REV 002, Ultrasonic Flow Meter, PFA, ½” (0 – 18 LPM, Z-shape calibration included), DSP Converter with display (24VDC, Signal output: 4-20mA, 2 Digital Outputs, 1 Digital Input, RS485) for monitoring chemical dispense flow rate.

- Keyed service interlock to interface with Omron PLC Controller.

- PFA Teflon tubing with PFA Teflon Primelock Fittings for Chemical fluid paths.

FM Approved 4910 compliant CRP1 PVC – Qty (1)

Bulk chemical delivery storage weldment to accommodate one each customers’ 55 gallon drum shipping container titled “Chemical #7 / EKC TMAH Chemistry” to interface with two each Wafer Process Systems Model WPS-SQFFH-1800-PVC, 18 foot FM Approved 4910 compliant Modularized CRP1 PVC Rear Access Square Front Fume Hood Wet Process System titled “Pre-Clean / Etch Wet Bench.”

Includes:

-

Clear CPVC hinged front door with Southco hinges and ¼ turn latches with door interlock switch to interface with Omron PLC controller.

-

Rolcon drum rollers with corrosion resistant PVC encapsulated roller face and spring retained axles.

-

Integral leak detection sensor located in weldment plenum to interface with Omron PLC Controller.

-

Shipping container low fluid sensor located in line from the container to the point of use chemical process vessel.

-

Machined Buttress Drum Adaptor for siphon port connection to shipping container drum.

-

Remote EPO mushroom switch on bulk chemical cabinet to interface with Omron PLC controller.

-

Digihelic Low Exhaust Monitor on bulk chemical cabinet to interface with Omron PLC controller.

-

12 VDC GLW® 10w 24 VDC LED Waterproof Flood Light.

-

Bulk chemical delivery storage weldment secondary containment drain connection with 1” ball valve.

-

White Knight Model PSA060 F12, PTFE Teflon pneumatic double bellows pump with flow controls (0- 60 LPM @ Ambient to 100 degrees C) for chemical dispensing to point of use chemical process vessel.

-

Yamatake secondary containment leak detection sensor located in weldment plenum to interface with Omron Zen PLC Controller.

-

Flowline EchoPod UG01-0001-41, reflective ultrasonic level transmitter with PVDF transducer, 4-20 mA two wire output to interface with PLC, ±0.2% of range accuracy, 4.9 foot maximum range with a 2” beam width, 2” MNPT connection and polypropylene IP68 rated enclosure. (For Waste Drum Level Sensing.)

-

PFA Teflon 2-way bulk chemical dispense valve located in chemical delivery storage weldment to interface with point of use chemical process vessel to be controlled by Omron PLC controller.

-

Futurestar Auto Valve Model 6BJ-4S-1B-204U, with a flow control range 0.25-18 LPM at 10-30 psid and 4-20 mA output for Closed Loop Control and ½” inlet, ½” outlet both S300 connections.

-

M-2111-F4110-D-Z-010 REV 002, Ultrasonic Flow Meter, PFA, ½” (0 – 18 LPM, Z-shape calibration included), DSP Converter with display (24VDC, Signal output: 4-20mA, 2 Digital Outputs, 1 Digital Input, RS485) for monitoring chemical dispense flow rate.

-

Keyed service interlock to interface with Omron PLC Controller.

-

PFA Teflon tubing with PFA Teflon Primelock Fittings for Chemical fluid paths.

Qty: 1

FM Approved 4910 compliant CRP1 PVC – Qty (1)

Bulk chemical delivery storage weldment to accommodate one each customers’ 55 gallon drum shipping container titled “Chemical #8 / Chemistry” to interface with two each Wafer Process Systems Model WPS-SQFFH-1800-PVC, 18 foot FM Approved 4910 compliant Modularized CRP1 PVC Rear Access Square Front Fume Hood Wet Process System titled “Pre-Clean / Etch Wet Bench.”

Includes:

-

Clear CPVC hinged front door with Southco hinges and ¼ turn latches with door interlock switch to interface with Omron PLC controller.

-

Rolcon drum rollers with corrosion resistant PVC encapsulated roller face and spring retained axles.

-

Integral leak detection sensor located in weldment plenum to interface with Omron PLC Controller.

-

Shipping container low fluid sensor located in line from the container to the point of use chemical process vessel.

-

Machined Buttress Drum Adaptor for siphon port connection to shipping container drum.

-

Remote EPO mushroom switch on bulk chemical cabinet to interface with Omron PLC controller.

-

Digihelic Low Exhaust Monitor on bulk chemical cabinet to interface with Omron PLC controller.

-

12 VDC GLW® 10w 24 VDC LED Waterproof Flood Light.

-

Bulk chemical delivery storage weldment secondary containment drain connection with 1” ball valve.

-

White Knight Model PSA060 F12, PTFE Teflon pneumatic double bellows pump with flow controls (0- 60 LPM @ Ambient to 100 degrees C) for chemical dispensing to point of use chemical process vessel.

-

Yamatake secondary containment leak detection sensor located in weldment plenum to interface with Omron Zen PLC Controller.

-

Flowline EchoPod UG01-0001-41, reflective ultrasonic level transmitter with PVDF transducer, 4-20 mA two wire output to interface with PLC, ±0.2% of range accuracy, 4.9 foot maximum range with a 2” beam width, 2” MNPT connection and polypropylene IP68 rated enclosure. (For Waste Drum Level Sensing.)

-

PFA Teflon 2-way bulk chemical dispense valve located in chemical delivery storage weldment to interface with point of use chemical process vessel to be controlled by Omron PLC controller.

-

Futurestar Auto Valve Model 6BJ-4S-1B-204U, with a flow control range 0.25-18 LPM at 10-30 psid and 4-20 mA output for Closed Loop Control and ½” inlet, ½” outlet both S300 connections.

-

M-2111-F4110-D-Z-010 REV 002, Ultrasonic Flow Meter, PFA, ½” (0 – 18 LPM, Z-shape calibration included), DSP Converter with display (24VDC, Signal output: 4-20mA, 2 Digital Outputs, 1 Digital Input, RS485) for monitoring chemical dispense flow rate.

-

Keyed service interlock to interface with Omron PLC Controller.

-

PFA Teflon tubing with PFA Teflon Primelock Fittings for Chemical fluid paths.