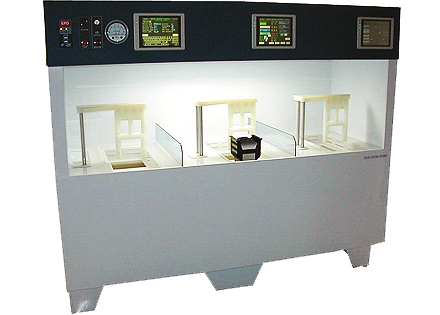

Semi-Automated Biomedical Bench

Wafer Process Systems Inc. performs in field modifications to existing equipment to accommodate process changes and/or safety and upgrades for our customers existing equipment without the need of extensive cost associated with the removal of existing equipment and installation of new equipment, including our semi-automated biomedical bench.

Overview of our Biomedical Bench (Semi-Automated)

Wafer Process Systems Inc. automation concepts which incorporate Dual Axis Linear or Rotary Motion Positioning Systems, in either pneumatic or servo applications, provide a wide range of cost effective methods for substrate handling. Automated Wafer Transfer Systems, for this wet bench type, is designed to accommodate a wide range of substrate sizes ranging from 100mm to 300mm single or dual wafer cassettes. Systems are available in multi substrate size capabilities which make it ideal for Fab transitions or for wafer reclaim processes which require various size substrate processing capabilities. The operator interface is via a touch screen panel which provides full graphical display of all positioning system parameters. The touch screen control incorporates an alarm status panel which prompts the operator in the event of any alarm conditions and a maintenance screen which allows maintenance personnel the ability to control all functions manually or in an automatic mode.

Model WPS-1000-FA-A-2002-3001

Semi-Automated Front and Rear Access Batch Chemical Process System

The Wafer Process Systems Inc. Model WPS-1000-FA-A-2002-3001 incorporates a Linear Servo Positioning Systems for two process vessel configuration or multiple process vessel configurations. The systems is designed to accommodate dual 100 MM, 150 MM, 200 MM and single 300MM wafer cassette handling to provide broader process capabilities. The positioning system movement is performed by an independent numerical controller and incorporates interpolated movement for reduced transfer times and smoother movements.

Model WPS-700-RA-A-150-200-1

Rear Access Semi-Automated 150 MM Batch Chemical Process System

The Wafer Process Systems Inc. Model WPS-700-RA-A-150-200-1 incorporates Linear Servo Positioning Systems for two process vessel front to rear configurations which use independent PLC controllers for each process module. All modules operated independently of each other and are provided with a UPS for additional product safety in the event of power outages. Operator interface is via a Colored Touch Screen located on front control panel. The PLC based controllers permit both manual and automated operation of the Servo Positioning System.

Model WPS-600-PVC-C, Y/Z/ Theta Series

Semi-Automated Front and Rear Access Batch Chemical Process System

The Wafer Process Systems Inc. Model WPS-600-PVC-C wet bench incorporates a Linear Servo Positioning Systems with a Rotary Theta Axis for multiple process vessel configurations. The systems is designed to accommodate single 75 mm, 100 mm and 150 mm wafer cassette handling to provide broader process capabilities. The Theta axis allows for front and rear process vessel configuration. The positioning system movement is performed by an independent numerical controller and incorporates interpolated movement for reduced transfer times and smoother movements.

Model WPS-400PVC-C, Y/Z Series

Semi-Automated Front and Rear Access Batch Chemical Process System

The Wafer Process Systems Inc. Model WPS-400PVC-C, incorporates a Linear Servo Positioning Systems for two process vessel configuration or multiple process vessel configurations. The systems are designed to accommodate single 75 mm, 100 mm and 150 mm wafer cassette handling to provide broader process capabilities.

Model WPS-800-FA-A-2001-3001

Semi-Automated Front Access Batch Chemical Process System

The Wafer Process Systems Inc. Model WPS-800-FA-A-2001-3001 incorporates a Linear Pneumatic Positioning Systems for two process vessel configuration. The systems are designed to accommodate single 200 MM and 300MM wafer cassette to provide broader process capabilities. The positioning system movement is performed by pneumatic linear actuators with flow precision controls for smoother movements that are protected by Gortex Bellows.

Model WPS-900-FA-A-2002-3001

Semi-Automated Front Access Batch Chemical Process System

The Wafer Process Systems Inc. Model WPS-900-FA-A-2002-3001 incorporates a Rotary Servo or Pneumatic Positioning Systems for two process vessel configuration or multiple process vessel configurations. The systems is designed to accommodate dual 100 MM, 150 MM, 200 MM and single 300MM wafer cassette handling to provide broader process capabilities.

Connect with us on LinkedIn and be informed of industry developments in the wet bench marketplace. CLICK HERE!