Computerized Electrochemical Deposition Wet Bench

Wafer Process Systems Inc. performs in field modifications to existing equipment to accommodate process changes and/or safety and upgrades for our customers existing equipment without the need of extensive cost associated with the removal of existing equipment and installation of new equipment, including computerized electrochemical deposition systems.

Computerized Electrochemical Deposition Wet Bench Overview

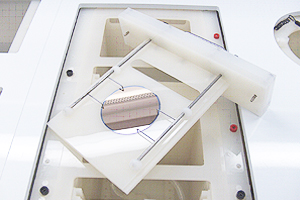

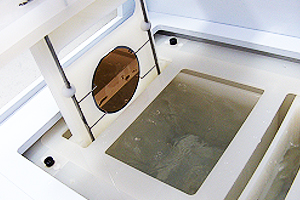

The WPS ECD-Au-4C Series, Electrochemical Deposition Wet Process System is designed to process Si, GaAs and Ceramic substrates for Au Electrochemical Deposition process using both Cyanide and Sulfide based solutions. The system is designed for use with Wafer Process Systems Inc. proprietary cathode and anode assemblies for processing single substrates in a horizontal orientation (Fountain Plating) for single side deposition or vertical orientation for single side deposition. The Plating Rectifier Interface is a 15 inch colored touch screen display with Windows® based software for local programming and monitoring of power supply settings. The interface can be remote or incorporated into the system weldment. The System is constructed out of flame retardant PVC-C, Kynar® (PVDF) or Halar® (ECTFE) for corrosion resistance to all process solutions. Safety and ergonomics are main aspects in the system design. All fluid components are accessible through removable front and rear access panels. All electrical components are accessible through front control panels and rear access panels and incorporate interlock switches with EPO interface for safety. Standard features include emergency power off circuit with remote mushroom switch, remote load center and contractor, Photohelic low exhaust indicator with audible / visual alarm and EPO interface to eliminate the ability to operate equipment in the event of no exhaust, N2 purged head case with purge pressure interlock and EPO interface, plenum liquid level monitor with audible / visual alarm and EPO interface with auto DI water shutoff, back wall and plenum exhaust, recessed deck with 360° lip exhaust to insure capture of fumes during transfer of wafers. All chemical wetted components are PVDF or PFA. All electrical components are UL, CSA or CE listed. All system electrical components are guaranteed for three years and All system DI Water components are guaranteed for three years and provide a 98% uptime.

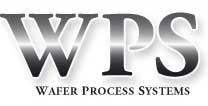

Electro Chemical Deposition System Cathode and Anode Assemblies

Wafer Process Systems Inc. PVDF cathode and anode assemblies are designed to accommodate 75 mm through 300 mm substrates for processing in a vertical orientation. Features include a one piece PVDF open back side design cathode assembly with integral handle and PFA Teflon coated stainless steel contact pins which rotate and latch the substrate into place with four point contact to substrate. The 90° rotating contact pins have knurled knobs for rotating the contact pins for easy placement and removal of substrate into the fixture. The cathode uses a PVDF dove tail assembly to interface with plating vessel cathode support track. The Anode is supported by an adjustable position assembly which enables the anode to be moved closer or farther away from the substrate to achieve the desired plating results.