Conveyorized PC Board Wet Process Equipment

Wafer Process Systems manufactures a comprehensive line of Conveyorized PC Wet Chemical Spray Process Equipment to perform various Cleaning, Photo Resist Develop, Acid Copper Etching, Alkali Copper Etching and Stripping applications commonly found in the Printed Circuit Board Manufacturing Industries.

Conveyorized PC Board Overview

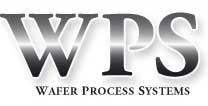

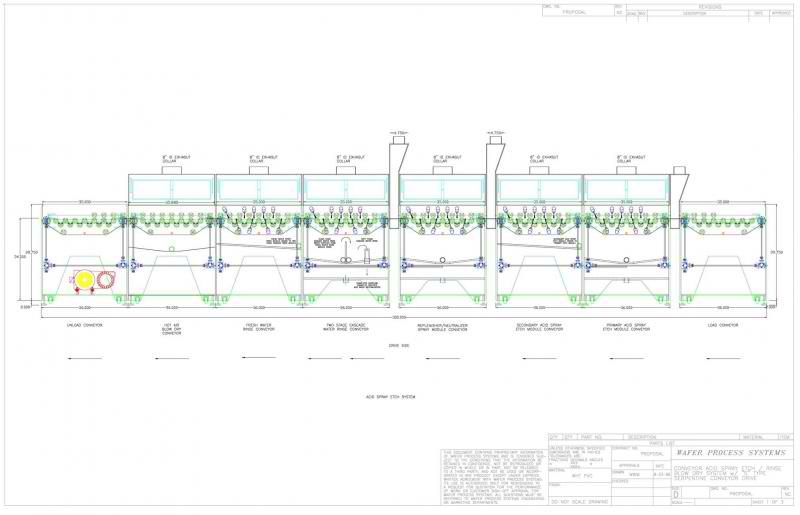

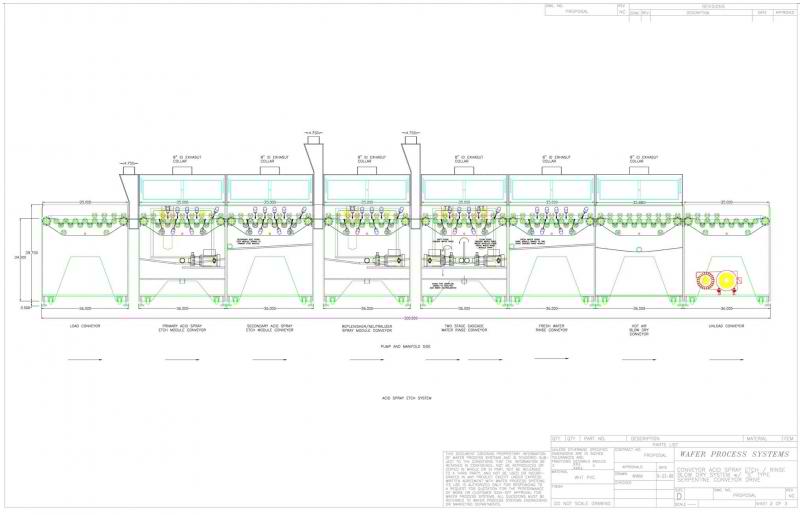

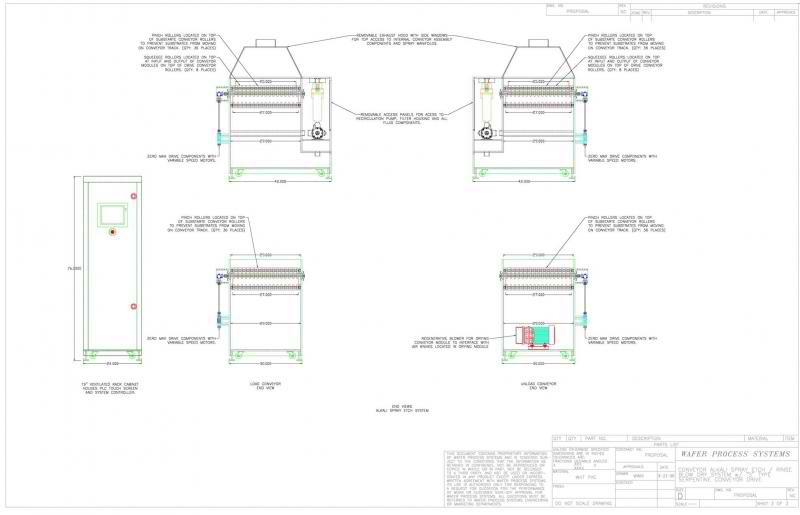

Wafer Process Systems Inc. offers two conveyor drive designs to accommodate a wide range of flexible and rigid printed circuit boards up to 30 inches wide. The Belt Drive design utilizes a single piece fluoropolymer mesh conveyor surface which can accommodate most flexible PCB’s without the use of support frames. The Serpentine Drive design utilizes a fluoropolymer belt for driving the conveyor wheels which are fabricated of corrosion resistant material. The Serpentine Drive is most suitable for rigid products and provides complete exposure of product surface during spray processes for increased uniformity.

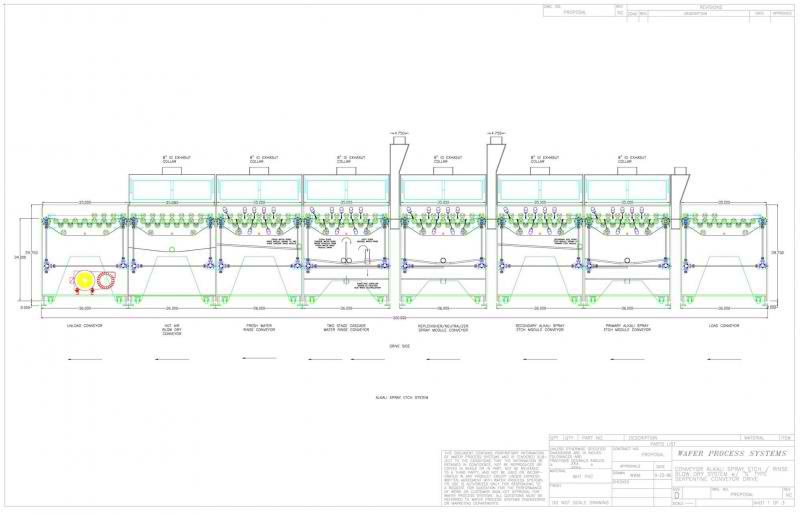

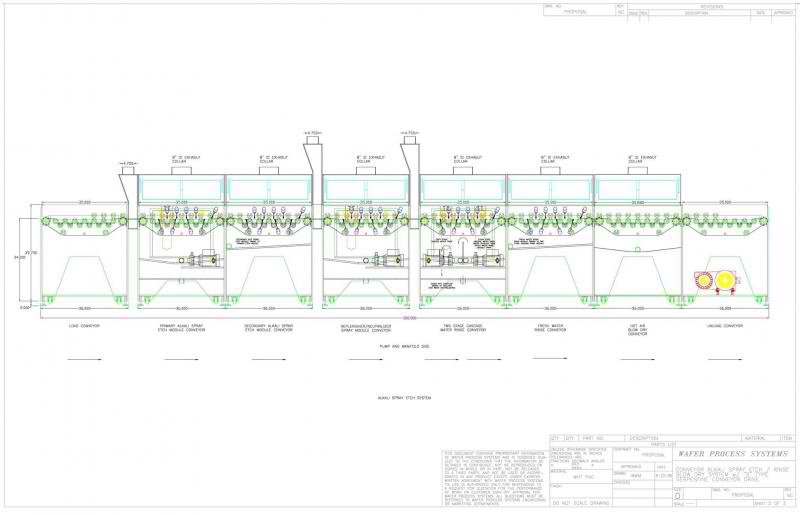

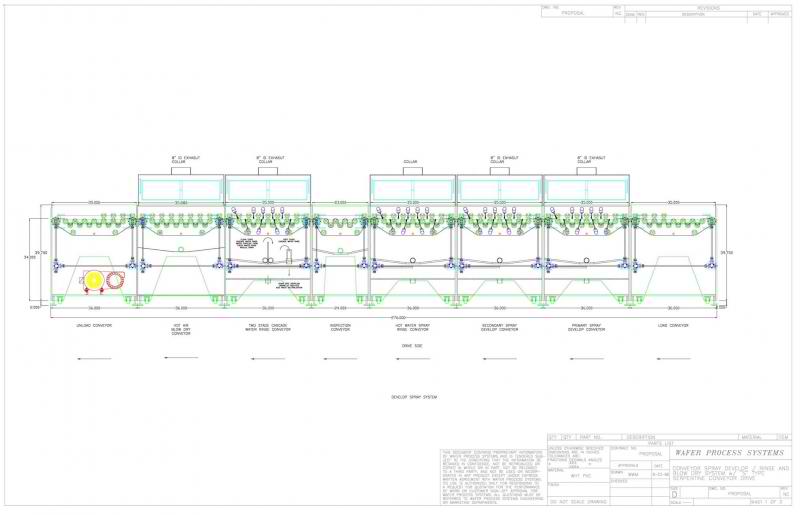

Conveyorized PC Spray Process Systems with Serpentine Drive

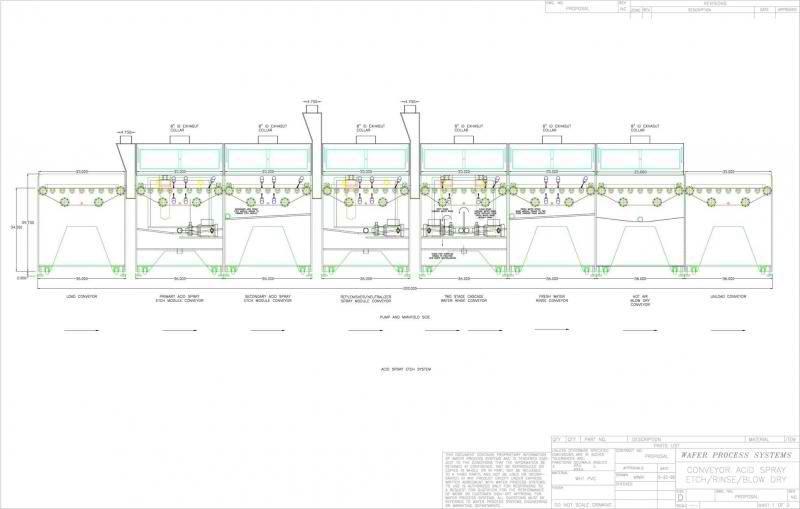

Acid Spray Etch System for PCB Etch Application

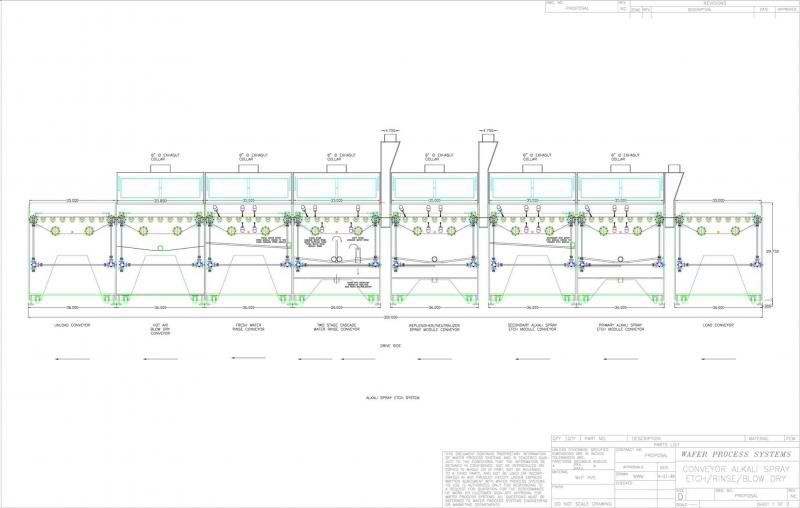

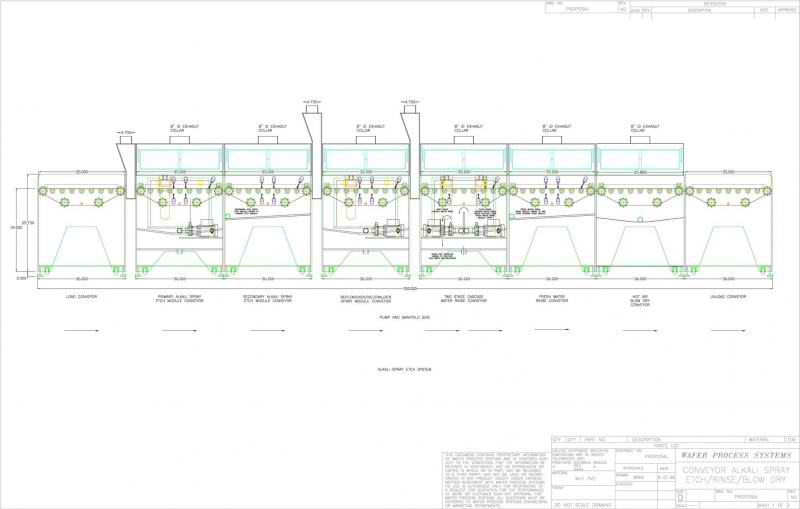

Alkali Spray Etch System for PCB Etch Application

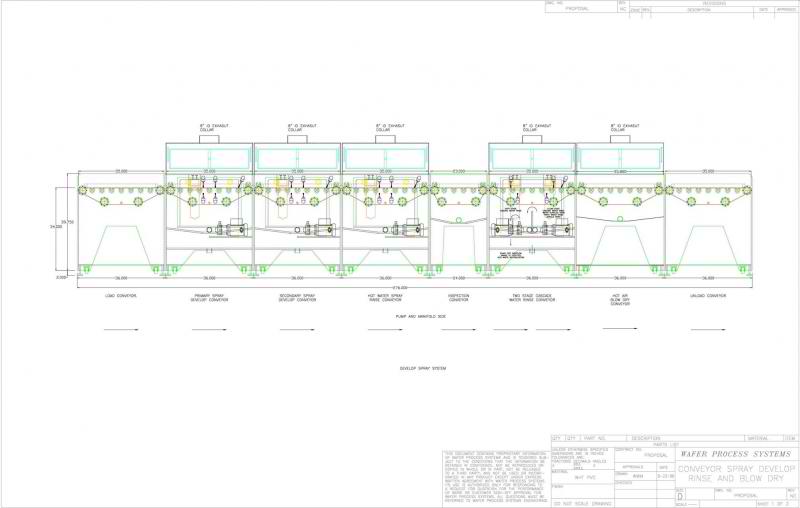

Photoresist Spray Develop System for PCB Photoresist Develop Application

Conveyorized PC Spray Process Systems with Belt Drive

Conveyorized Acid Spray Etch System for PCB Etch Application

Alkali Spray Etch System for PCB Etch Application

Were you looking for Conveyorized RFID Equipment?