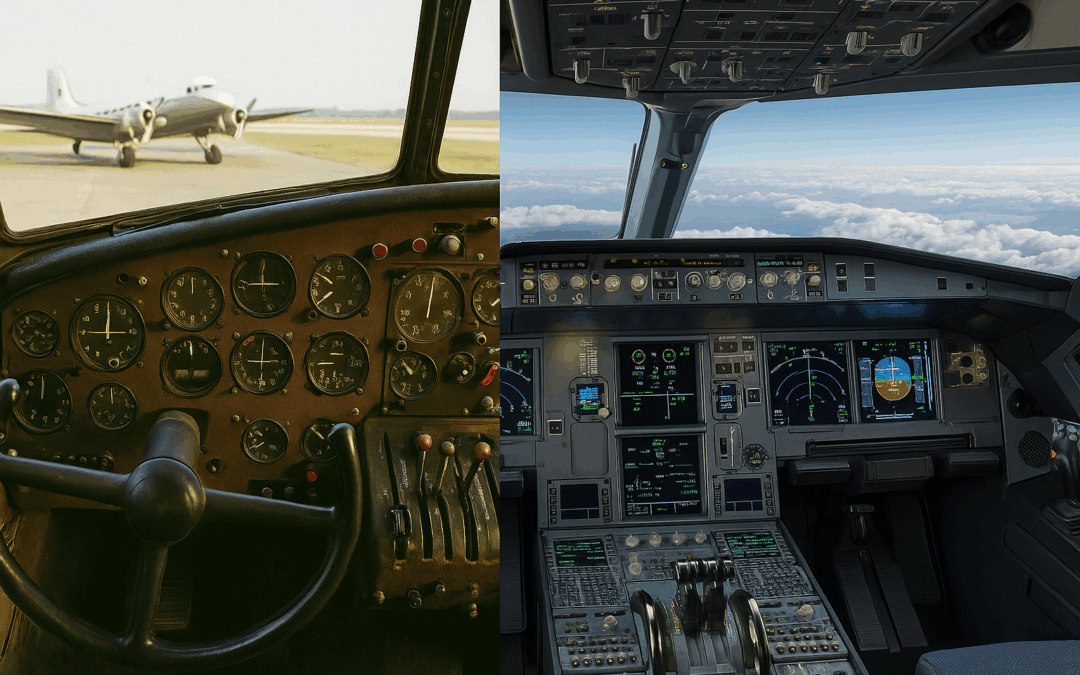

The commercial aviation industry has witnessed a revolutionary transformation since the 1950s, a decade often romanticized as the golden age of air travel. While the in-flight service and style of that era are fondly remembered, what truly distinguishes then from now is the leap in technology—especially in computing power. The modern commercial airplane is not just a vehicle for transport but a flying data center, orchestrating thousands of real-time processes that ensure safety, efficiency, and comfort.

The Simplicity of the 1950s Cockpit

In the 1950s, commercial airliners such as the Douglas DC-6 or the Lockheed Constellation relied heavily on analog systems. Flight crews manually controlled most functions using mechanical instruments and visual references. Autopilot was rudimentary at best, typically maintaining altitude or heading but not adjusting for turbulence, traffic, or changing weather. Navigation required celestial charts or radio beacons, and even communication was limited to voice transmissions over radio frequencies.

Computers were virtually nonexistent in aviation at that time. Any “automation” was achieved through gyroscopes, pressure sensors, and magnetically-driven indicators. A typical aircraft might have had a few basic control systems but nothing even close to digital computation. Decision-making depended almost entirely on pilot skill and experience.

The Digital Revolution Takes Flight

Fast forward to today, and the contrast is stark. Modern airliners like the Boeing 787 Dreamliner or Airbus A350 operate with avionics systems that can process billions of instructions per second. These aircraft are equipped with multiple redundant flight control computers, which continuously calculate data from dozens of sensors to adjust aerodynamics, engine performance, cabin pressure, and even route optimization in real time.

Today’s planes carry embedded systems running sophisticated software for autopilot, fly-by-wire technology, terrain avoidance, and air traffic management. For example, fly-by-wire replaces manual flight control with electronic interfaces that interpret pilot input and make micro-adjustments to optimize performance and safety. This requires enormous computing capability to evaluate variables such as speed, air pressure, altitude, and actuator position every millisecond.

The Modern-Day Data Stream

Modern commercial airplanes generate and transmit gigabytes of data per flight. Engine performance, fuel consumption, environmental conditions, maintenance diagnostics, and even passenger behavior data are continuously monitored and analyzed. Some systems are connected via satellite to ground-based data centers for real-time predictive maintenance and flight operations monitoring.

This evolution parallels advances in semiconductor design and manufacturing. The precise etching and wet process equipment—such as that developed by Wafer Process Systems—play a crucial role in producing the microchips that power avionics and flight computers. Without the advancements in semiconductor fabrication, the digital infrastructure in today’s airplanes would not be possible.

Looking Ahead

As the aviation industry embraces AI, machine learning, and more autonomous capabilities, the demand for powerful, compact, and reliable computing will continue to rise. Commercial aircraft of the future may be able to predict and prevent system failures, reroute themselves dynamically, and interact seamlessly with ground-based systems—all thanks to continued innovation in both aviation and semiconductor technologies.

In essence, the journey from the 1950s to now is not just a story of air travel—it’s a testament to the exponential growth in computing power and the critical role companies like Wafer Process Systems play in enabling the future of flight.