Solar Bench (Photovoltaic)

Wafer Process Systems Inc. performs in field modifications to existing equipment to accommodate process changes and/or safety and upgrades for our customers existing equipment without the need of extensive cost associated with the removal of existing equipment and installation of new equipment, including our solar bench (photovoltaic).

Solar (Photovoltaic) Wet Bench Overview

Wafer Process Systems Inc. manufactures Automated Solar Cell Batch Wet Chemical Process Lines for Post Saw Cleaning, Saw Damage Etching, Acidic and Alkaline Texturization, Pre Cleaning, PSG Etching, Oxide Etching, Pre Nitride Deposition Cleaning, Glass Substrate Cleaning and Glass Substrate Etching.

The above Manual Solar Cell Batch Wet Chemical Process Line was manufactured for the Government of Egypt to perform Saw Damage Etching, Texturization, Oxide Etching and Neutralization Processes with substrates being transferred through the chemical and rinse processes using a manually operated transfer hoist for cassette carrier transfer.

Wet Process Systems are designed for single or multiple cassette processing. Positioning System uses single transfer mechanism or optional multiple transfer mechanism for higher throughput.

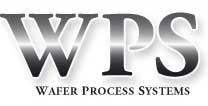

100 wafer four cassette 125 mm Solar Cell Process Line for Post Saw Clean and Adhesive Removal

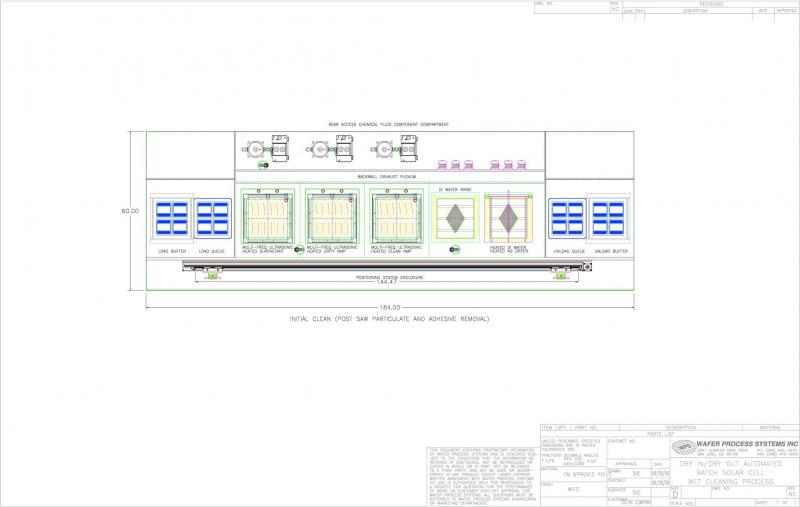

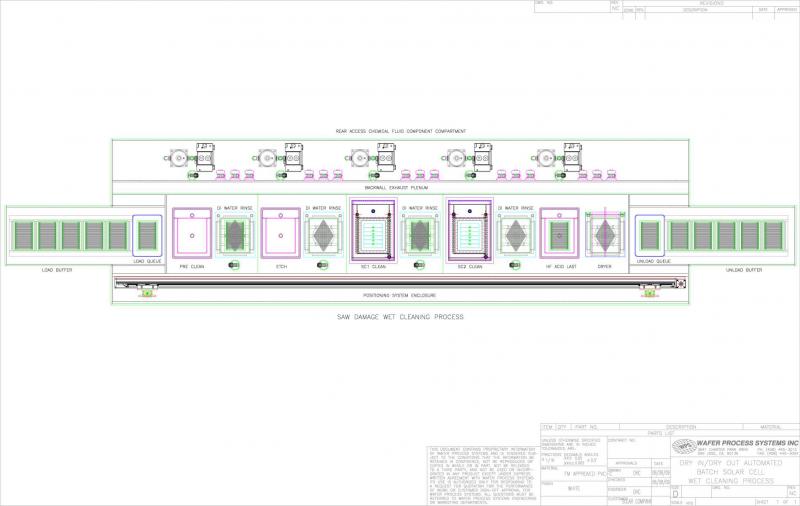

50 wafer single cassette 156 mm Solar Cell Process Line for Saw Damage Clean and Etch